Farm Machine

Home>Farm Machine

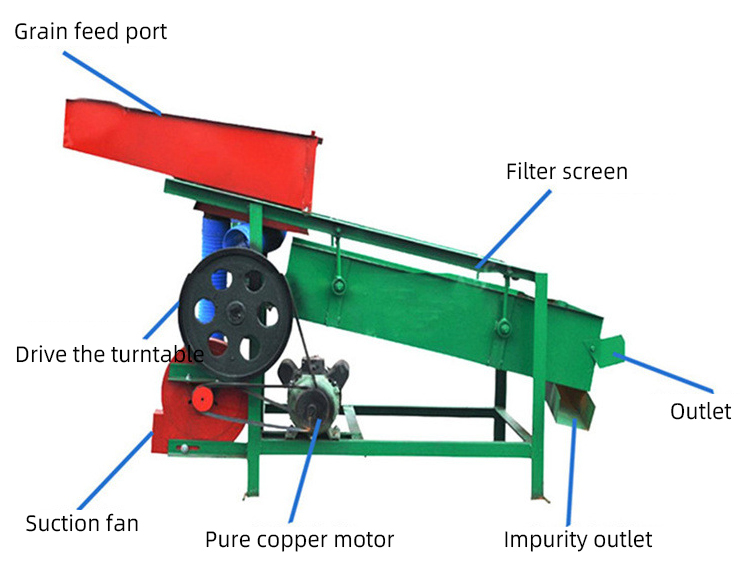

Grain screening machine is used to clean up dust, small stones, leaves, bran skin, deflated grain, moldy grain and other debris in corn, wheat, soybean, rice, buckwheat, peanut, sunflower seeds, sorghum and other grains. A new type of grain cleaning equipment, this series of equipment has multiple functions such as dust removal, specific gravity screening and grading screening. Compared with similar grain machines, this machine has the characteristics of large screening capacity, high cleaning rate, convenient movement and simple operation. Widely used in large and medium livestock farms, feed mills, farms, grain processing centers, and grain cleaning and screening in grain purchase points.

The working principle of the screening machine

Carry out the initial sieving and sieving, and use a relatively large mesh to sieve large impurities, such as corn cob, soybean flakes, peanut skin and so on. Large impurities will remain in the layer screen, and the motor will screen and shake back and forth, and the debris will be vibrated to the debris outlet. The materials that need to be screened will leak into the lower screen, and the next screen will be screened. , the mesh is relatively small, that is, the small impurities of the grain machine, and the mesh of the screen is larger than the material that needs to be screened.

Product analysis

Product application

This product can sort corn, soybean, wheat, rice, rapeseed, melon seeds, beans, tea, wool and other grains

Due to different products, the size of the screen used is also different, contact us for more information.

Different crops, different screens

This product can choose screens with different apertures according to the user's screening needs.

Features

1.There is no dust during screening, which greatly changes the screening environment. The screening rate of this machine reaches 98%. The air volume can be adjusted according to the specific gravity of the material, the screening weight of crops can reach 5t/h, and the total power is 3KW.

2.On the basis of the ordinary grain machine, this machine is equipped with an additional air-selection device, and it carries out material conveying and screening by means of screw conveying, which has a good effect on reducing grain fur and dust pollution.

Product display

Advantages of small cleaning sieve

The selected sieve is a two-layer sieve. First, it is drawn by the fan at the feed inlet, and the light-weight miscellaneous leaves or wheat straw are directly removed. ) falls directly onto the lower screen, and the lower screen will directly miss the small impurities, pebbles, and defective grains (seeds) in the grain (seeds), and the intact grains (seeds) will be screened out from the discharge port . This small grain cleaning machine solves the single function of the hoisting machine, which cannot effectively remove the defects of stones and soil clods, and can bring satisfactory results to cleaning and net selection of grain (seeds). The machine has the advantages of small footprint, convenient movement, easy maintenance, obvious dust and impurity removal efficiency, low energy consumption, and easy use. It can be said to be a fighter in small and medium grain cleaning and screening!

Installation and commissioning of small cleaning screen

1: Debugging of the running direction of the grain cleaning machine. After connecting the power supply, (1 motor switch) lightly tap the motor switches one by one to confirm the running direction of the motor of the grain cleaning machine (please press the running direction arrow on the device), and lightly touch the switch The time should not exceed 3 seconds, and the equipment can be operated normally only when the direction is confirmed to be correct!

2: Adjustment of the level The grain cleaning machine needs to be placed on a relatively flat ground to work, and it is better for all four wheels of the grain cleaning machine to touch the ground.

| Model | KLCZ-900 | KLCZ-1000 | KLCZ-2000 |

| Type | Linear vibrating screen | Linear vibrating screen | Linear vibrating screen |

| Screen material | Metal wire screen | Metal wire screen | Metal wire screen |

| Size | 1500*900*820mm | 1800*1000*920mm | 2000*1100*950mm |

| Weight | 70kg | 100kg | 130kg |

| Mesh size | 2.0-20mm | 2.0-20mm | 2.0-20mm |

| Feed particle size | 1.0-20mm | 1.0-20mm | 1.0-20mm |

| Capacity | 500-1000kg/h | 1000-3000kg/h | 3000-5000kg/h |