Farm Machine

Home>Farm Machine

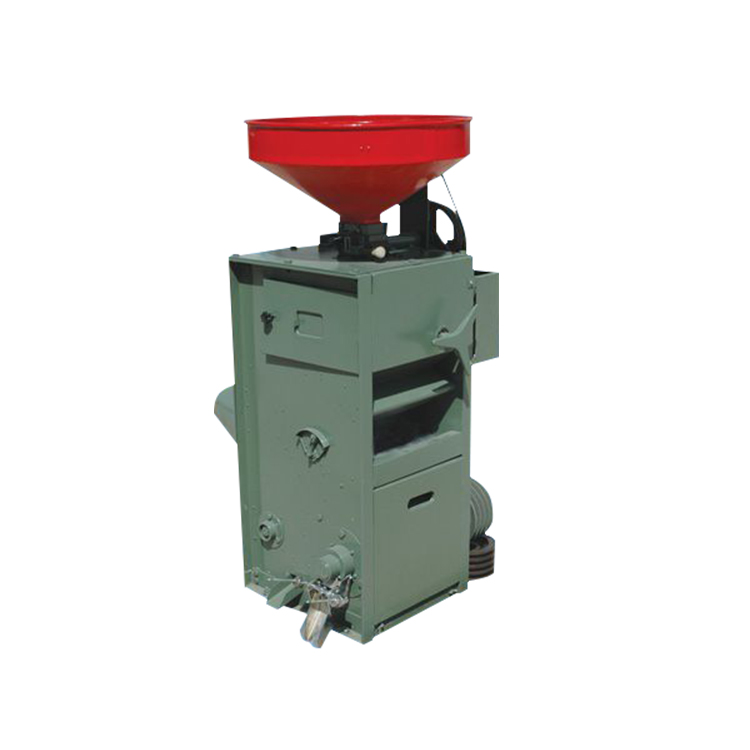

This model is a special small-scale equipment for paddy-processing. It is composed of feeding hopper, husker, brown rice and chaff separator, milling and blower, etc. It processes from paddy cleaning, husking, air-blowing selection to milling in a row. The brans, chaffs, blighted grains and white rice will be selected out from different outlets separately. This machine has been designed by proper layout, compact structure, reliable lightened main body. Thanks to the design, the rice mill features with low noise, easy operation, low power consumption and high productivity but with less chaff containing and less broken rice. It is an ideal machine for the countryside rice milling.

Working principle of rice mill machine

Firstly, paddy enters into the rice mill machine through vibrating sieve and magnet device;

Then, passes rubber-roller for hulling.

After, air blowing and air jetting to the milling room, the paddy finishes the process of husking and milling in succession.

Finally, husk, unripe paddy, and white rice are expelled out of the machine respectively. The dust collector collects the fine rice husk.

Features of rice mill machine

1. This machine can remove paddy husk, whitening rice, crush rice husk at one time;

2. The rice milling machine is easy to operate with less power consumption and high productivity;

3. with Iron roller that the rice has low breakage;

4. Low temperature when working.

Working procedures of rice mill machine

Rice goes into machine via vibrating screen (removing stones) and magnet unit (removing little piece of steel),and then passes through hulling room (remove the yellow husks), winnowing room,milling room (remove the brown chaff, and then become white rice), and blowing room in turn.

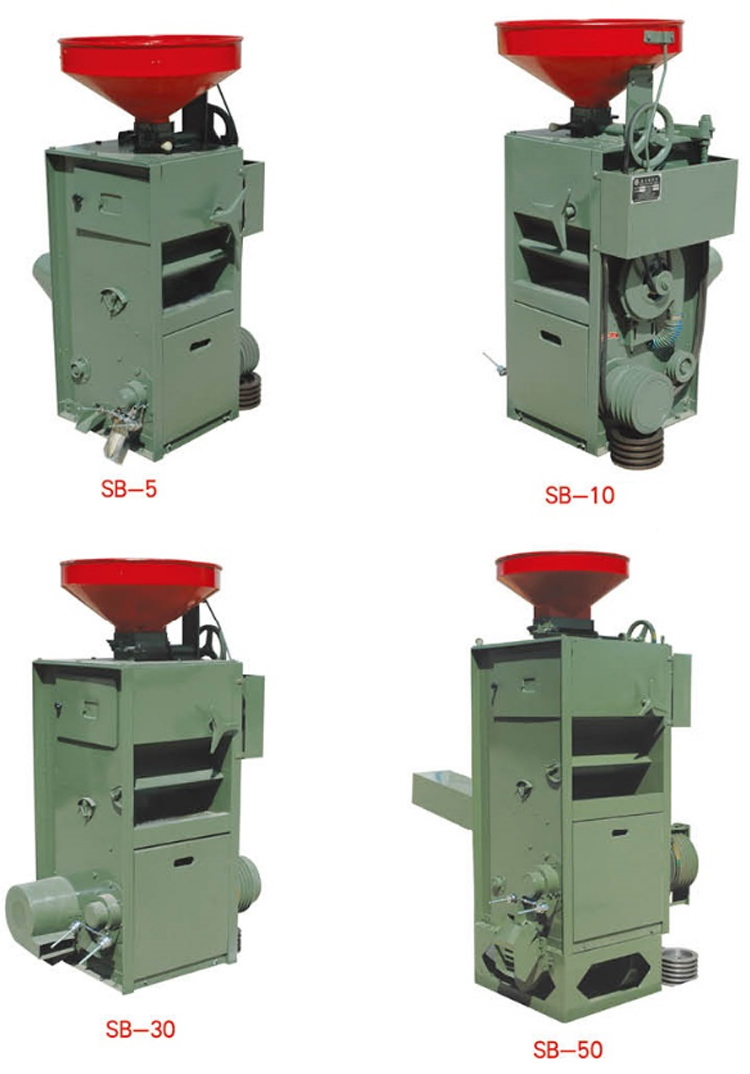

Product model display

Product display

| Model | SB-5 | SB-10 | SB-30 | SB-50 | |

| Output (kg/h)

(vary with paddy) |

500-600 | 900-1200 | 1100-1500 | 1800-2300 | |

| Power | Motor(kW) | 5.5 | 11 | 15 | 22 |

| Diesel engine(HP) | 8-10 | 15 | 20-24 | 30 | |

| Weight(kg) | 130 | 230 | 300 | 560 | |

| Measurement(mm) | 860×692×1290 | 760×730×1735 | 1070×760×1760 | 1070×760×1760 | |

| Packing size (mm)

(not including engine) |

650×670×1290 | 750×750×1750 | 960×750×1750 | 960×750×1750 | |